Acrel Equipment Operation & Maintenance Solution: Smart Energy Monitoring for Optimal Performance and Energy Savings

Comprehensive Power Monitoring for Critical Assets – Transform Your Facility Management with Real-Time Intelligence

Unlock the Full Potential o Your Equipment with Acrel’s Advanced Energy Metering Solutions

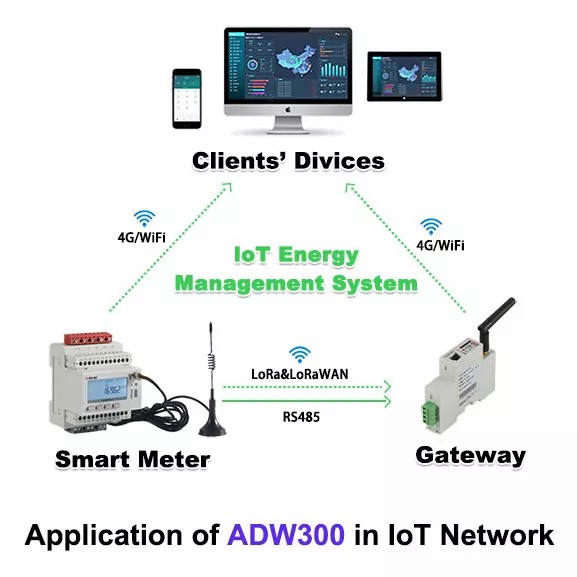

In today’s competitive industrial landscape, ensuring equipment reliability while minimizing energy costs is paramount. Acrel’s Equipment Operation & Maintenance Solution leverages cutting-edge smart energy meters and IoT technology to provide 24/7 monitoring of electrical parameters and operating hours for transformers, pumps, fans, and other critical equipment—delivering actionable insights that prevent failures and drive significant energy savings.

Two Core Capabilities, One Powerful Solution

1. Equipment Health Monitoring: Ensuring Correct Operation 24/7

Prevent costly downtime before it happens. Acrel’s multifunctional energy meters continuously track essential electrical parameters and runtime data, enabling predictive maintenance and immediate anomaly detection.

Key Monitoring Capabilities:

Transformers: Real-time tracking of voltage, current, active/reactive power, power factor, harmonic distortion, and temperature deviations

Pumps & Motors: Precise measurement of current fluctuations, phase imbalance, and operating cycles to detect cavitation, bearing wear, or overload conditions

Fans & HVAC Systems: Monitoring of startup current profiles, running hours, and energy consumption patterns to identify efficiency degradation

Other Critical Equipment: Customizable parameter tracking for compressors, conveyors, and specialized machinery

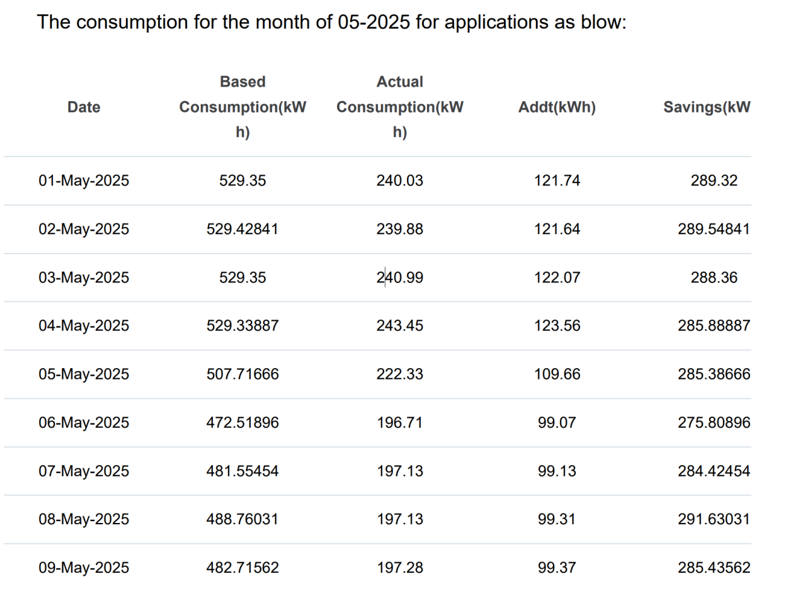

2. Energy Consumption Analytics: Automated Savings Reports

Transform raw energy data into strategic cost reduction. Acrel’s cloud-based energy management platform automatically generates comprehensive energy audit reports, identifying waste and optimization opportunities across your facility.

Intelligent Energy Reporting Features:

Equipment-Level Energy Accounting: Separate consumption data for each transformer, pump, or fan to identify high-consumption units

Benchmarking & Baseline Analysis: Compare current performance against historical data or industry standards

Load Profile Optimization: Identify peak demand contributors and shift non-critical loads to off-peak hours

Energy Efficiency Rating: Automatic calculation of equipment efficiency (kWh per unit output) with trend analysis

ROI Verification: Quantify savings from implemented measures with before/after comparisons

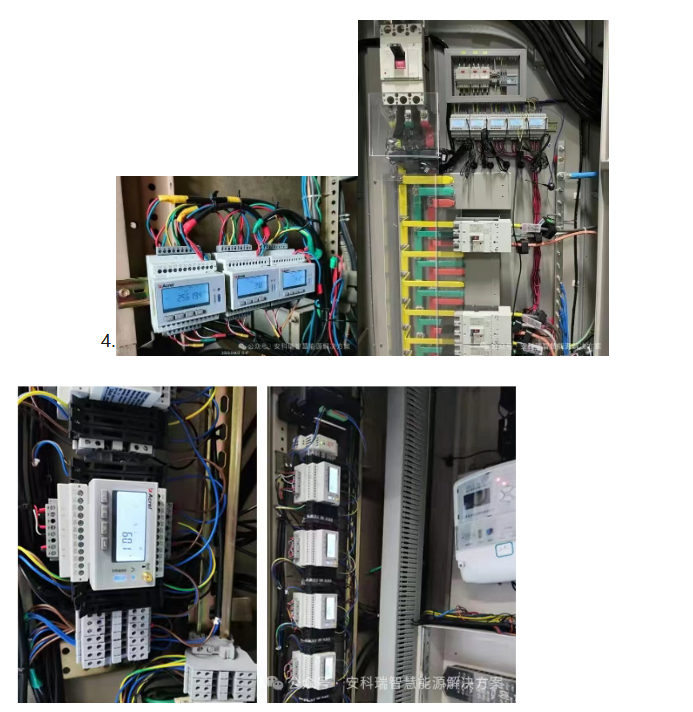

3. Case Study

Post time: Dec-01-2025