Is a Power Quality “Crisis” Approaching? The APView Power Quality Online Monitoring Device Delivers Precise Diagnostics for Harmonics, Flicker and Voltage Sags!

I. Current Status of Power Quality Monitoring in Various Industries

1.1 Wind Power Generation: Harmonics (mismatch between generators and power electronic devices); voltage deviation (start-up and shutdown of wind turbine generators); frequency deviation will occur in small isolated power grids.

1.2 Solar Power Generation: Harmonics (inverters); voltage fluctuation and flicker (random fluctuation of output power); DC component (inverters).

1.3 Data Centers: Harmonics (switching power supplies, UPS, frequency conversion equipment).

1.4 Petrochemical Industry: High sensitivity to voltage fluctuation, i.e., “momentary voltage dip” (which may cause shutdown of petrochemical plants); voltage sag (caused by large motors and motor groups).

1.5 Metallurgical Industry: Harmonics (speed control devices of rolling mills and large blowers); voltage fluctuation (arc furnaces).

1.6 Semiconductor Industry: High sensitivity of equipment.

II. Demand Analysis of Power Quality Monitoring

With the improvement of automation level in the electrical environment, the proportion of various nonlinear loads represented by power electronic technology, such as rectification, inversion and frequency conversion, is constantly increasing. In addition, due to imperfect regulation methods and external interference, the power quality has declined. A large number of precision electronic instruments controlled by computers and microprocessors are used in national economic enterprises, which are increasingly sensitive to power supply quality and put forward higher requirements for power quality. Thus, power quality problems and their solutions have gradually become a research hotspot.

The Measures for the Administration of Power Quality (Interim) points out that the administration of power quality shall follow the principle of “standard guidance, prevention first and comprehensive treatment”. Power generation, supply and consumption parties shall implement the concept of active prevention and control of power quality throughout the whole process of project planning, design, construction and operation, so as to jointly maintain a safe electrical operation environment.

To improve the power quality of the power grid, it is necessary first to conduct accurate detection and analysis of power quality, measure the power quality level of the power grid, analyze and determine the causes of various power quality problems, so as to provide a basis for the improvement of power quality.

Ⅲ. APVIEW SERIES POWER QUALITYANALYZER

1. Monitoring Functions – Steady-State Monitoring

Measurement of voltage, current, power, electric energy, etc.; voltage deviation; voltage unbalance; current unbalance; harmonic voltage/harmonic current; interharmonic voltage/interharmonic current; harmonic power; harmonic phase angle; total harmonic distortion (THD); high-frequency harmonics; voltage fluctuation and flicker; rapid voltage change. Monitoring data is displayed on the device interface, allowing viewing of real-time waveforms and fault waveforms.

2. Monitoring Functions – Transient Monitoring

Capturing voltage sag events, locating voltage sag sources, and analyzing sag tolerance curves.

Short-Time Interruption: A phenomenon in the power system where the root-mean-square (RMS) value of the power-frequency voltage at a certain point suddenly drops below 0.1 p.u., and then returns to normal after a short duration ranging from 10 ms to 1 min.

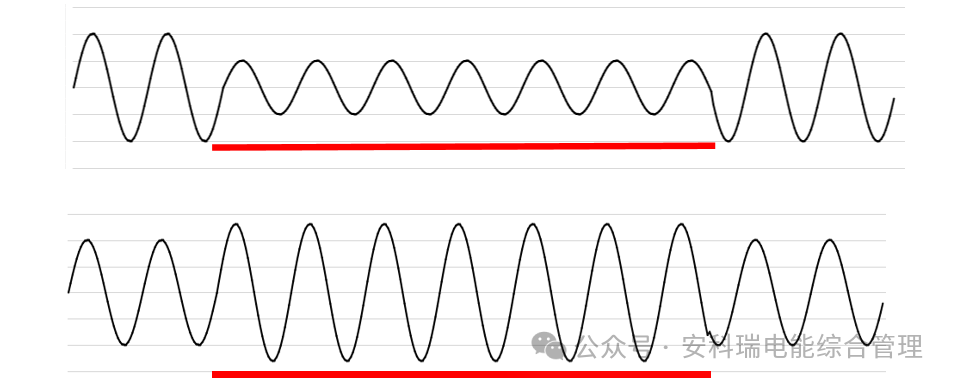

Voltage Sag: A phenomenon in the power system where the RMS value of the power-frequency voltage at a certain point suddenly drops to the range of 0.1 p.u. to 0.9 p.u., and then returns to normal after a short duration ranging from 10 ms to 1 min.

Voltage Swell: A phenomenon in the power system where the RMS value of the power-frequency voltage at a certain point temporarily rises to the range of 1.1 p.u. to 1.8 p.u., and then returns to normal after a short duration ranging from 10 ms to 1 min.

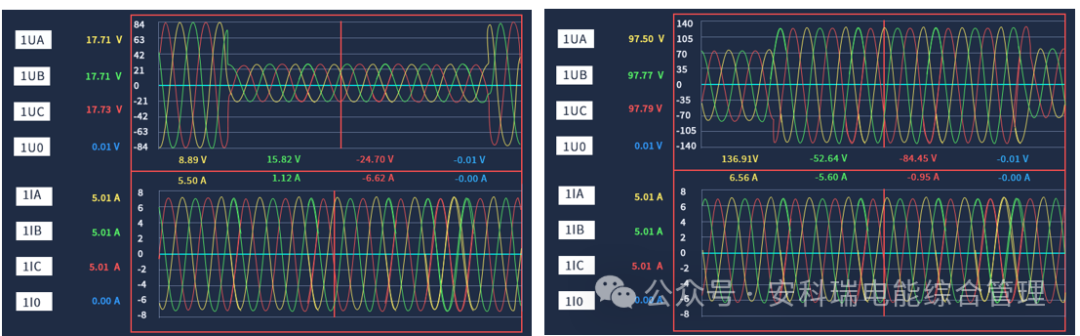

By retrieving data such as waveforms and electrical parameters during the occurrence and termination of faults, the equivalent impedance method is used to identify and analyze the location of impedance mutations, so as to determine whether the voltage sag source is on the line side or the bus side.

3. Monitoring Functions – Instantaneous Monitoring

Voltage transient monitoring and current transient monitoring. Event records and fault oscillograms at the moment of faults can be viewed on the device interface and the web terminal.

Transient State: Refers to a single change of voltage and/or current under steady-state conditions, with a duration of less than several cycles. It generally includes two types of phenomena, namely impulsive transients and oscillatory transients.

4. Monitoring Functions – Fault Waveforms

Voltage deviation, frequency deviation, voltage swell, voltage sag, short-time voltage interruption, and voltage transient.

COMTRADE is a data file format suitable for transient waveforms and event data obtained from power system models.

5. Monitoring Functions – Recording and Storage

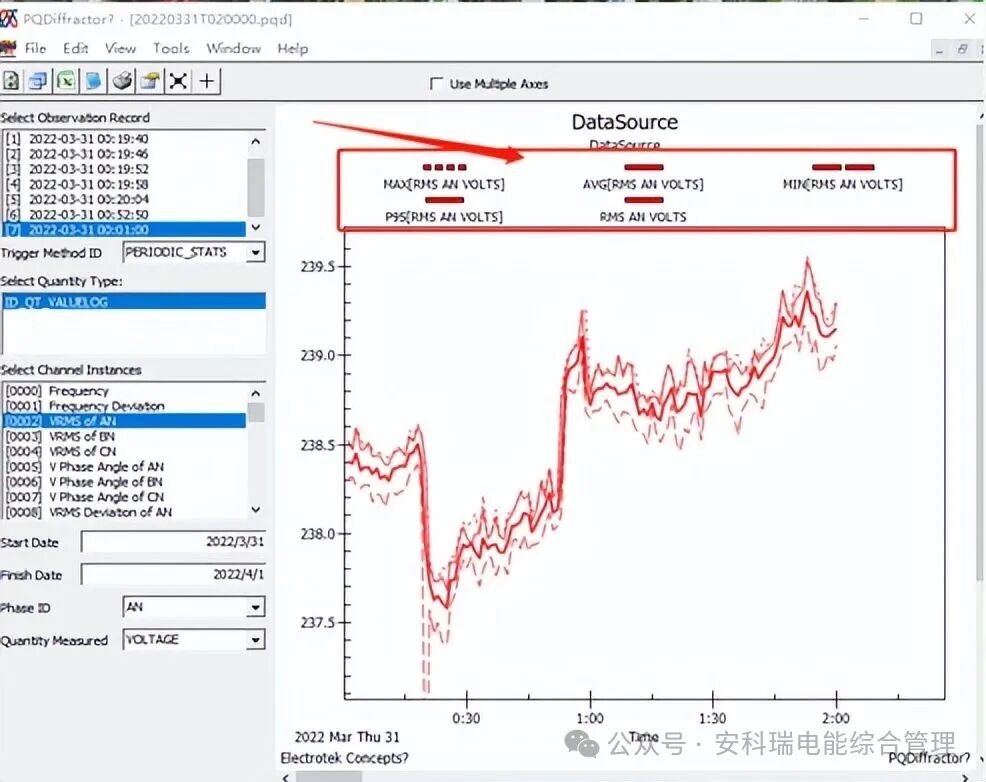

PQDIF data storage, data export, event records saved as PQDIF format files, and compressed files of steady-state data within 2 hours.

The storage chip capacity reaches 32 GB, which realizes real-time storage of monitoring point data. The 1-minute data (including mean value, maximum value, minimum value, 95% probability value, and root-mean-square value) can be stored on the device for up to 3 months, after which the data is updated following the first-in, first-out (FIFO) principle.

The PQDIF data type complies with the specifications of the DL/T 1608 Power Quality Data Exchange Format, and PQDIF data shall be storable for 90 days. The PQDIF data and fault oscillogram data recorded by the device can be saved locally via the FTP protocol.

6. Monitoring Functions – Web Server

Steady-state monitoring, transient monitoring, instantaneous monitoring, fault oscillography, qualification rate statistics, etc.

IV. Application Cases of Power Quality Online Monitoring

4.1 Semiconductor Industry – A High-end Semiconductor Wafer R&D and Manufacturing Project in Shanghai

Project Requirements

The client is primarily engaged in the R&D, production and sales of high-quality semiconductor wafers, as well as the import and export of goods and technologies. The deployment of power quality online monitoring devices is designed to focus on the monitoring of voltage swells/sags, voltage flicker, voltage harmonics/interharmonics, current harmonics/interharmonics, and other key parameters. By conducting scientific analysis on the voltage and current of the power distribution system based on the collected electrical parameter data, the real-time power quality status can be reflected in a more timely, accurate and responsive manner. This ensures the stable and reliable operation of the entire plant and minimizes equipment damage and property losses arising from voltage quality issues.

Solution Configuration

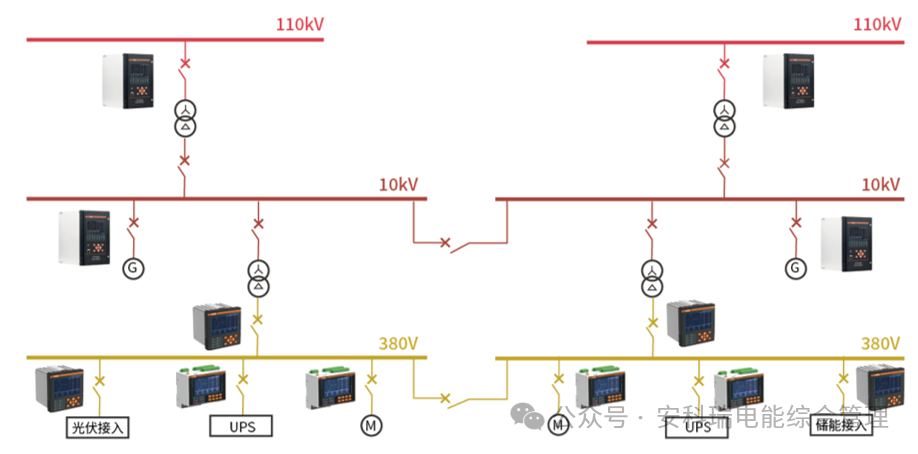

The power distribution system of this project comprises 1 switching station and 3 10kV substations. Each power distribution system adopts a dual-incoming-line and single-bus-tie configuration. One APView500 power quality online monitoring device is installed at each of the two incoming line sections of every substation, with a total of 8 devices deployed to monitor the power quality of all incoming line circuits. To enable real-time monitoring of the entire power supply system operation and data acquisition, the project is equipped with an AcrelEMS enterprise microgrid energy efficiency management platform, which achieves full-coverage monitoring from the 35kV down to the 0.4kV power consumption side.

4.2 Semiconductor Industry – An Electronic Material Manufacturing Project

The primary power quality issues in the semiconductor manufacturing industry are as follows:

Harmonic Problems

IC test stations, PLC-controlled manipulators, wafer processing equipment for chip fabrication, and frequency-conversion controlled semiconductor equipment are all major sources of harmonic distortion. These harmonics not only trigger malfunctions in the equipment itself, but the harmonic currents that feed back into the power grid can also cause overheating in other circuits, misoperation of electronic switches, and unstable supply voltage. In severe cases, they may even lead to production line shutdowns and the scrapping of semi-finished products. Furthermore, the frequent load switching of high-energy equipment – including epitaxial equipment, diffusion equipment and ion implantation equipment – exacerbates the deterioration of the power consumption environment.

Voltage Sag and Interruption

Modern semiconductor production equipment is highly susceptible to power quality fluctuations. Compared with traditional industries, semiconductor and LCD manufacturing processes are particularly sensitive to voltage sags: a voltage sag with an amplitude of 85%–90% of the rated value that lasts merely 16ms can suffice to trigger equipment shutdown. In the event of a short-time interruption, the load is generally completely disconnected from the power supply system (with voltage amplitude dropping below 10% of the rated value).

Both voltage sags and short-time interruptions can result in equipment downtime for the semiconductor industry. However, the occurrence probability of voltage sags is significantly higher than that of short-time interruptions. Relevant surveys indicate that voltage sags account for 70%–80% of all power distribution system faults, while in transmission system faults, the proportion of incidents caused by voltage sags exceeds 90%.

Post time: Jan-04-2026